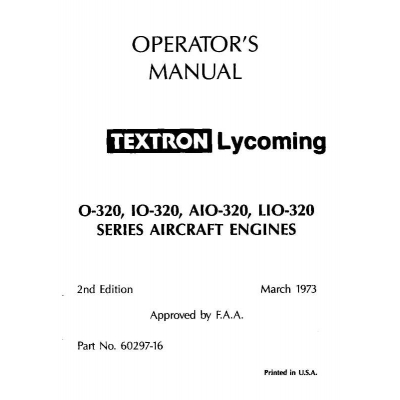

Lycoming O-320-E3D Traditional Aircraft Engines. Mel, Thanks for the info. This engine came off of a Warrior, it had 1200 hours on it and suffered a prop strike. Lycoming O 320 E2d Parts date released: october 2011 title: o-320-e2d & -e3d parts catalog document part number: pc-203-6 models affected: o-320-e2d, o-320-e3d O-320-E2D & -E3D Parts Catalog lycoming.com Standards, the following chapters apply to the O -320-E2D, -E3D.

THE HEALTH OF YOUR ENGINE

The engine compression check or differential pressure test is integral to determining the health of an engine. Most people in the aviation community are familiar with the test but not many really know how or why it’s done. Here is a quick look at how a basic engine compression inspection is carried out and some follow up actions that maybe necessary as a result of the test.

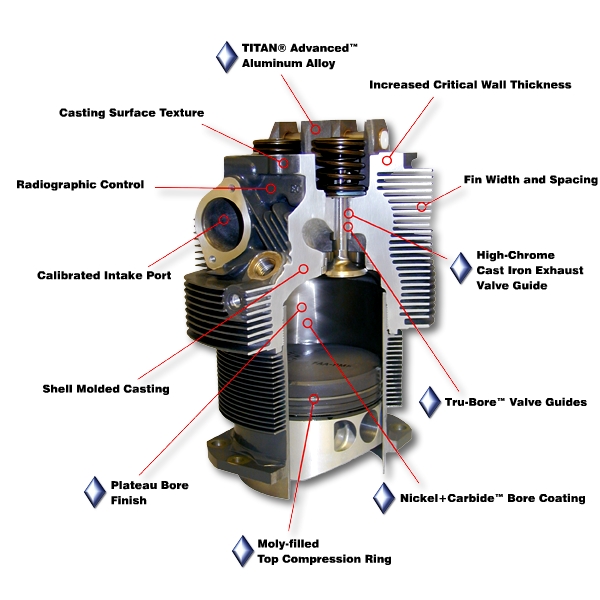

The engine compression inspection checks the condition of the working parts in the combustion chamber of a cylinder. This is accomplished by measuring the static leak rate of the cylinder as compared to the leak rate through an orifice of specified size. This is done by attaching a differential compression measuring device, which incorporates the orifice, two pressure gauges, with a regulator to one spark plug hole of the cylinder under test while the piston is at top dead center of the compression stroke.

Lycoming recommends a compression check of the cylinders any time you encounter loss of power, increasing oil consumption, hard-starting, or evidence of unexplained abnormal operation, and to check the health of the engine at 100 hour or annual inspection intervals.

Before the inspection, the engine must be run until the cylinder head and oil temperatures are in the normal range. The test should be completed as soon as practical after shut down. A differential compression measuring device is attached to the cylinder via the spark plug hole after the piston is positioned at top dead center of the compression stroke. Shop air is supplied to the tester and the regulator is adjusted to 80 PSI as air is sent is to the cylinder through the tester. To assure that the piston rings are seated, the propeller is moved slightly back and forth with a rocking motion. The cylinder compression reading is taken from the gauge on the downstream side of the orifice and recorded as “X” psi over 80. Pressure readings for all cylinders should be nearly equal. Each engine manufacturer sets the limits for differential pressure and the appropriate service information should be referenced for this criteria.

Lycoming offers the following guidance. A difference of 5 psi between cylinders is satisfactory; a difference of 10 to 15 psi indicates an investigation should be made. Unless the pressure difference exceeds 15 psi the investigation does not necessarily mean removal of the cylinder. A follow-on compression check should be made within the next 10 hours of operation to determine the wear rate. If the pressure reading is below 60 psi or if the wear rate increases rapidly, as indicated by an appreciable decrease in cylinder pressure, removal and overhaul or replacement of the cylinder(s) should be considered.

Lycoming 0 320 E3d Manual Instructions

YOU CAN SAVE COSTS

Failing to warm up the engine or to do the 10-hour recheck can be expensive. The cold engine shortcut might save time before the test but it may fail to properly identify a poorly operating cylinder. Conversely, often during the 10-hour operating period, valves reseat themselves and compression improves to acceptable levels, thereby saving the cost of a cylinder.

Questions, please contact:

Cessna Customer Care

316-517-5800 or 1-800-423-7762

[email protected]

Airplane Aircraft Digital Manuals in PDF Format as Download for Owners, Parts Catalog, Maintenance, Troubleshoot, Repair, Overhaul, Service & Information Manuals for the Cessna, Piper, Continental, Lycoming Aircraft Engines and many more.

Lycoming 60294-5-4 Geared and Geared Supercharged Aircraft Engines Repair Overhaul Manual

This 174 pages illustrated Overhaul Manual in Pdf Download for the 1970 - 1976 Avco Lycoming Part # 60294-5-4 Geared and Geared Supercharged Aircraft Engines.CONTENTS BELOW:SECTION I - INTRODUCTIONSEC..

Lycoming 60294-5-6 Geared and Geared Supercharged Aircraft Engines Repair Overhaul Manual

This 253 pages illustrated Overhaul Manual in Pdf Download for the 1970 - 1996 Lycoming 60294-5-6 Geared and Geared Supercharged Aircraft Engines.CONTENTS BELOW:SECTION I - INTRODUCTIONSECTION II - GE..

Lycoming 60294-6 Integral Accessory Drive Aircraft Engines Repair Overhaul Manual

This 133 pages illustrated Overhaul Manual in Pdf Download for the 1975 - 1996 Avco Lycoming Part # 60294-6 Integral Accessory Drive Aircraft Engines.CONTENTS BELOW:1 - Introduction2 - Gen..

Lycoming 60294-7-4 Direct Drive Engine Repair Overhaul Manual

This 93 pages illustrated Engine Overhaul Manual in Pdf Download for the 1974 Lycoming Direct Drive Engine Part Number 60294-7-4.Contents below:INTRODUCTIONGENERAL DESCRIPTIONGENERAL OVERHAUL PROCEDUR..

Lycoming 60294-7-9 Direct Drive Engine Repair Overhaul Manual

This 152 pages illustrated Overhaul Manual in Pdf Download for the 1974 - 2002 Avco Lycoming 60294-7-9 Direct Drive Engine.CONTENTS BELOW:1 - Introduction2 - General Description3 - G..

Lycoming 60294-8 Vertical Helicopter Engines Repair Overhaul Manual

This 172 pages illustrated Overhaul Manual in Pdf Download for the 1978 Avco Lycoming 60294-8 Vertical Helicopter Engines.CONTENTS BELOW:INTRODUCTIONGENERAL DESCRIPTIONGENERAL OVERHAUL PROCEDURESIGNIT..

Lycoming 60294-8-3 Vertical Helicopter Engines Repair Overhaul Manual

This 176 pages illustrated Overhaul Manual in Pdf Download for the 1978 - 2001 Avco Lycoming 60294-8-3 Vertical Helicopter Engines.CONTENTS BELOW:1 - Introduction2 - General Description3 &..

Lycoming 60298-1 Aviation Engines Repair Overhaul Manual

This 69 pages illustrated Overhaul Manual in Pdf Download for the Avco Lycoming Model O-290-D2 Series Aviation Engines 60298-1.CONTENTS BELOW:1- General Description2- Overhaul Tools3- Disassembly of E..

Lycoming 60298-3 Aircraft Engines Repair Overhaul Manual

This 114 pages illustrated Overhaul Manual in Pdf Download for the Avco Lycoming Models O-360 and O-540 Series Aircraft Engines Part # .CONTENTS BELOW:1- Introduction2- General Description3- General O..

Lycoming 60298-4 Aircraft Engines Repair Overhaul Manual

This 73 pages illustrated Overhaul Manual in Pdf Download for the Avco Lycoming O-320 and O-340 Series Aircraft Engines Part # 60298-4.CONTENTS BELOW:1- Introduction2- General Description3- General Ov..

Lycoming 76 Series Engines 60294-9-2 Repair Overhaul Manual

This 230 pages illustrated Overhaul Manual in Pdf Download for the 1980 Avco Lycoming 76 Series Engines Part # 60294-9-2.CONTENTS BELOW:1- Introduction2- General Description3- General Overhaul Procedu..

Lycoming Avco 60294-6 Integral Accessory Drive Aircraft Engines Overhaul Manual

This 80 pages illustrated Overhaul Manual in Pdf Download for the 1975 - 1996 Avco Lycoming 60294-6 Integral Accessory Drive Aircraft Engines.CONTENTS BELOW:SECTION 1. INTRODUCTIONSECTION 2. GENERAL D..

Lycoming GO-480, GSO, IGO, and IGSO-480 Series 60297-14-2 Aircraft Engines Operators Maintenance Manual 1973

This 112 pages illustrated Operators Maintenance Manual in Pdf Download for the Lycoming GO-480, GSO-480, IGO-480 and IGSO-480 Series Aircraft Engines Part Number 60297-14-2 (Revision 1976 and 1980).C..

Lycoming IGO-540 and IGSO-540 Series 60297-15-1 Aircraft Engines Operators Maintenance Manual 1974

This 94 pages illustrated Operators Maintenance Manual in Pdf Download for the 1974 Lycoming IGO-540 and IGSO-540 Series Aircraft Engines Part Number 60297-15-1 (Revison 1976).CONTENTS BELOW:SECTION 1..

Lycoming IO-540-B1A5 Overhaul Manual Supplement

This 60 pages illustrated Overhaul Supplement Manual in Pdf Download for the Lycoming IO-540-B1A5.The purpose of the Overhaul Supplement is to enable personnel to overhaul the IO-540-B1A5 Series Lycom..

Lycoming 0 320 E3d Manual Pdf